What Is OmniChannel?

At a high level, OmniChannel is the latest retailing tactic that combines IT and supply chain to increase the efficiencies in sales. There are plenty of examples of OmniChannel, like purchasing online and doing an in store pick up. Another example would be a store is out of stock of a particular item you are looking for and a sales associate will order and ship it to you. One an example that I had the pleasure of listening was from the CIO of Brooks Brothers, Sahal Laher, present on their implementation of OmniChannel. The example Sahal gave was: imagine the end customer is in Massachusetts and is looking for a sweater to add into his wardrobe for the winter season. He finds the perfect sweater on the Brooks Brothers website and makes the purchase. Behind the scenes, the software will determine where to fulfill the order whether it is from the distribution center or from a store like Florida where the climate does not get cold enough to sell through all the sweaters.

Many retailers are doing this because if you can sell the product in the store first, then they will maximize the revenue. If they cannot sell it in the stores, items will be discounted then sent off to the outlet stores at a further discount off the manufacturer’s suggested retail price. Thus, they will earn less and less in revenue. If this cycle continues, it creates downward pressure on the brand and the brand becomes diluted. When this continues, savvy shoppers will just wait until the product hits the outlet shelves and not the retail stores perpetuating an ugly cycle for a retailer.

OmniChannel Is Awesome When It Works

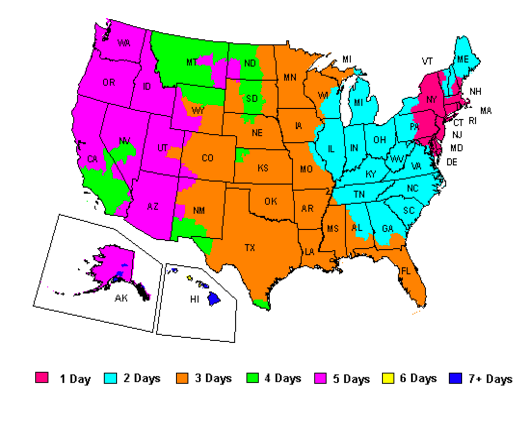

It’s possible to leverage a retail store as a distribution center. Here is a map of the ground service level from Fedex in New York City:

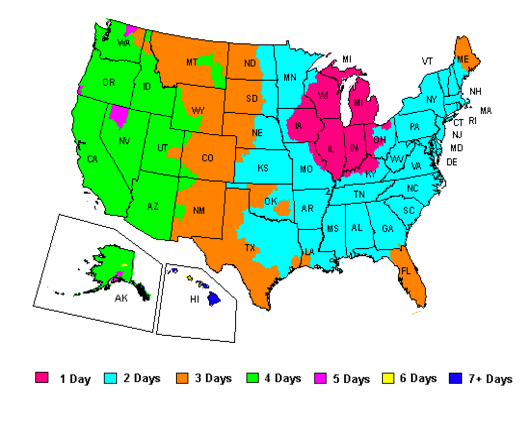

Here is a map from Chicago:

Notice how the service level changes depending on the origin of where the package ships? You can play around with the tool on Fedex here.

Let’s use the Brooks Brothers example again. Imagine a customer from Texas in the Dallas-Fort Worth area orders that sweater. Now the Brooks Brothers system needs to determine if it is distributed from their warehouse in Connecticut (assuming they only have one facility for forward and reverse logistics) which has a very similar service level as the NYC map or from a flagship store on Michigan Ave in Chicago. The Dallas-Fort Worth area has a 3 day service level from NYC and 2 day service level from Chicago. There’s a lot that happens in the background to make a determination, but let’s make it simple with a “perfect world” fulfillment using ground shipping. The system makes a calculation and determined:

- The Chicago store has a decent demand (sales) for this particular sweater

- There is a planned replenishment for the sweater from Connecticut and will arrive less than 5 business days

- Shipping and workforce management calculations were done to determine the lowest cost

The system then sends the order to the Chicago store because it would be cheaper to have the store fulfill it because of the upcoming replenishment, cheaper labor, shipping was cheaper from Chicago to Texas compared to Connecticut, and the customer will receive it one day earlier.

OmniChannel Is Awful Because Retailers Are Not Ready

Best Buy is one leader of OmniChannel and Wall Street rewarded them 2 years ago because of the way they were able to keep up the margins because they used the stores as a mini distribution center. The stores that had less demand for certain items were fulfilling online orders before the product went onto clearance. Their OmniChannel solution even surpassed Amazon’s delivery time:

According to StellaService, which shops hundreds of retailers online anonymously to track their performance in various areas, said that for the first time ever Best Buy has consistently beat Amazon in order delivery time. Best Buy’s average delivery time from October through April has declined to 3.3 days, beating Amazon’s 3.6 days during the same period.

The new capability for Home Depot, who is battling with trying to find the source for an alleged data breach, mirrors a ship-from-store program being unveiled by Target ahead of the coming holiday season at 140 stores. Target will ultimately have the ability to reach 91% of U.S. households by ground transit within one to two days.

OmniChannel is very important because there are other aspects to satisfy a customer. As briefly discussed, you can order online and pick up in store and that has been a huge driver to sales because a customer does not need to wait in line or have to look for the item in store. This is great for people like us because we can use a portal and earn some extra miles and let someone else do the leg work for us on the picking and packing.

OmniChannel sounds great on paper, but it does not work all the time. As I have ramped up reselling, I’ve seen some good and bad store fulfillment. You can instantly tell when it’s a store fulfillment or a distribution center fulfillment. Let’s play a game and see if you can figure out which ones are store fulfillments:

Great job with the security seal there Worst Buy pic.twitter.com/8lpiRESzXh

— Vinh (@MilesperDay) November 14, 2015

Take a look at Vinh’s picture, and let me know what you think?

How about another one from Vinh?

Count on Worst Buy to ship you an iPad Air 1 when you ordered a Mini 4. #Noteventhesamesize

— Vinh (@MilesperDay) January 4, 2016

Let’s take a look at what happened to my buddy @saianel. We will start with the first picture and you should read through all of the tweets and updates about it:

Why would deliver packages like this? This is completely unacceptable @Macys @FedEx pic.twitter.com/93EjXF8mAl

— Saianel (@saianel) January 30, 2016

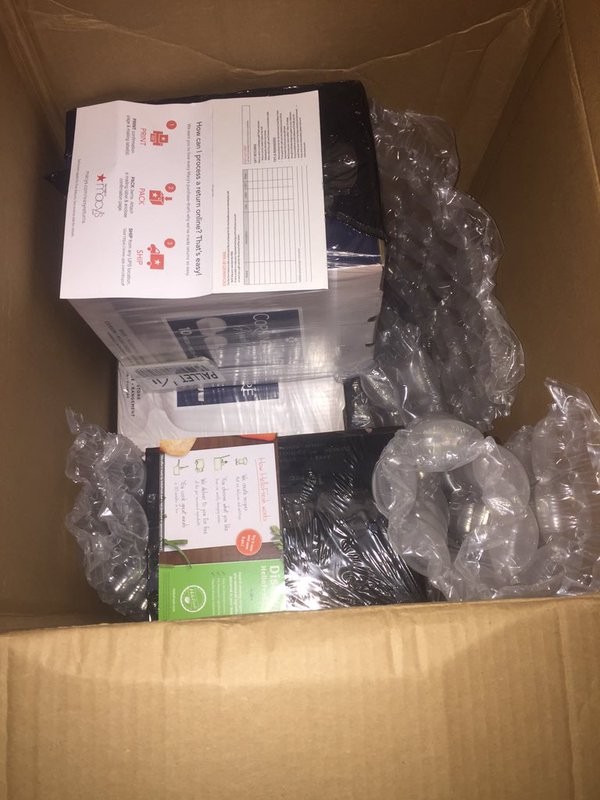

In one of his tweets he posted this picture:

Look at how much space is in the box! There’s not enough dunnage and protective bubble wrap. Everything was broken inside.

If you guessed that all three are store fulfillment, that’d my guess too and here’s why. Stores are not prepared for OmniChannel.

Vinh’s Orders

The first tweet is poor packaging, the idea of using security tape is a great idea, but if it is not packaged properly like Vinh’s case, what’s the point? A simple solution for Best Buy should have been to add more dunnage so the box does not become compressed and have something like that happen. Then add tape to the middle to seal the box shut and then add another layer on each side of the middle tape to hold the box together.

You have people who do not know how to package a box, the information technology infrastructure is not there, or even the workspace. What Vinh had to go through from Best Buy is beyond me when they shipped him the wrong iPads. My speculation for that mix up is because of the store has a small area to work on the outbound shipments and confused the Best Buy employee. What I am surprised is how the system was able to let a shipment like that go out the door. In a typical order management system, the clerk can only work on one order at a time. Then they will scan the invoice and the screen will display item and quantity for the carton. Then they will scan each item to confirm the item is going into the box, for electronics, another scan of the serial number will be done.

Saianel’s Order

This part annoys me the most as a reseller. I can’t tell if it’s the system failing or the people needing the tools and training. I bought some big bulky items and each order was packaged differently which instantly told me it was store fulfilled. Many of packages were exactly like Saianel’s. It looked like someone sat on it and the box was in terrible shape. Fortunately, my products were able to take the massive beating.

With Saianel’s order we do not know if the Macy’s employee DGAF and that’s why it was packaged that way. We also don’t know if that particular Macy’s had any smaller boxes or that was the smallest box size and they did their best to ensure there would be no damage to the goods, but the box was simply too big. This is the most frustrating because you don’t know what you will get, broken products upon delivery or product that’s fine, but a box so smashed up you have extra work to send into Amazon. If the order was fulfilled from an actual Macy’s distribution center, I can guarantee the package would have arrived perfectly for Saianel. The insides would have been packaged well with the right box size because the proper supplies are there and the warehouse management system would have told the shipping clerk the right carton size.

How You Can Tell If The Order Is From A Store

Example 1

A friend of mine found an awesome clothing product and wanted to sell on Amazon and had a series of questions. The potential profit margin was awesome, the rank was fantastic, and was not gated creating a perfect ideal scenario. Outside of that, the only thing you need to make sure to send in the clothing is to make sure it is in a polybag that has a suffocation warning with a visible UPC. She tested the scenario with a small order, and low and behold, none of the clothes that arrived were in a polybag. That is a dead give away it came from the stores. All the manufacturers mail the clothes in a plastic bag because distribution centers are dirty and dusty. To enhance the customer experience in stores, retail employees open all the packaging to these items and put them on shelves as part of their visual merchandising. Bottom line to tell if it’s from a store: for clothes, if it’s not in a poly bag, it’s from the store.

Example 2

Ever wonder why you order 5 units of the same small item from Best Buy and you get more than one package? Obviously, it’s because they are fulfilling from various locations instead of one central location. This one is difficult to pin point due to the stocking levels in the store. This is a multi echelon inventory optimization scenario where the system determined which stores to fulfill even if one location could have completed the order.

OmniChannel Is Fascinating

Before I left my job in New York, I was on an OmniChannel team we were in the process of rolling things out for it beginning with a mobile store. In this post we discussed the operations side of it, but again, OmniChannel is a broad word to describe the ecommerce aspect of it like buying on a mobile device versus the traditional method, on a desktop computer. Supply chain management is a another area that I find fascinating. When it doesn’t work, we have great frustration as an end customer.

If you’re curious about SCM and want to learn more, shoot me an email. If there’s topic you’d like to learn more about regarding the supply chain let me know. If I don’t know the answer, I know plenty of people in the industry.

I guess this explains the iPad that BB shipped me in a Jiffy bag, which meant it arrived with crushed corners. Probably fine but disappointing if it’s for myself, bad if it’s a gift and a real pain if I was planning on reselling it.

Yea – that happened to me too from BB, I was fine with it, but if I were to resell, it’d be unacceptable

I bought my iPad looking just like that. But I knew it upfront, bought from a consolidator and saved 250 on a brand new 64g iPad Air because the box looked bad. Definitely worth it for me.

But I’d have hesitated to buy it like that for resale.

Yeah, I returned it to the store. I wanted to exchange it for one that was in better shape, but they aren’t stocking them anymore. So, I lost out on what would’ve been a great money maker. I considered eBay, but knew I’d take a hit on the price because of the banged up box, and didn’t want to deal with the extra hassle. So disappointing when you’ve found a great deal for resale and then it arrives in unsaleable condition.

Kohl’s is another hopeless victim of OmniChannel fulfillment. The stores do not have boxes or tape, all they have are thin, poly shipping bags meant for clothing. But they will ship everything in these bags. Toys, ceramics, glass, anything. And of course everything arrives in pieces or smashed to hell. I waste more time returning items than they’re worth, so I will think long and hard before I ever order form Kohl’s again to determine if the item I want to order will survive shipping by itself with no padding or protection whatsoever.

I’ve even heard of Kohl’s slapping a shipping label on the product itself which is totally unacceptable. I can only imagine how much money they’re losing by doing things like this. It is certainly one way to drive customers to other companies.

That sounds awful, I haven’t sourced from Kohl’s yet, but I will keep that in mind

So that’s why I got 2 orders where the security thing was still on the clothing! I had to go down to the store to take it off!

Wow that’s insane!!

Definitely shipped from a store since warehouses don’t put that on.

And their loss prevention needs to look at that store fulfillment and fix that process up. Just imagine, someone who works at the store, brings in prepaid label and sends product to themselves or an accomplice. Management is going to have a huge problem.